The chemical vapor deposition (CVD) method for synthesizing diamond can better control crystal orientation, thickness, purity, and perform quantitative doping. In addition to being used for manufacturing lab-grown diamond jewelry, it has excellent application prospects in many high-tech fields such as chips, microelectronics, quantum, optics, ultra precision machining, high-end medical, etc.

Crydiam successfully developed the first MPCVD reactor with complete intellectual property rights in China in 2013; produced the first MPCVD single crystal diamond in 2014; built the first MPCVD industrial production line in 2015. Today, Crysdiam has 1500 MPCVD reactors, far ahead in production scale.

Crysdiam’s CVD Production Workshop

High-quality and low-cost production of large single crystal diamond seeds

The growth of CVD single crystal diamond requires obtaining flat single crystal diamond seed that meet the requirements of crystal orientation and have smooth upper and lower surfaces, while strictly controlling the edges and overall defects of the seed crystals. Preparing qualified large single crystal diamond seed is the first challenge for controlling costs and improving quality in CVD diamond synthesis.

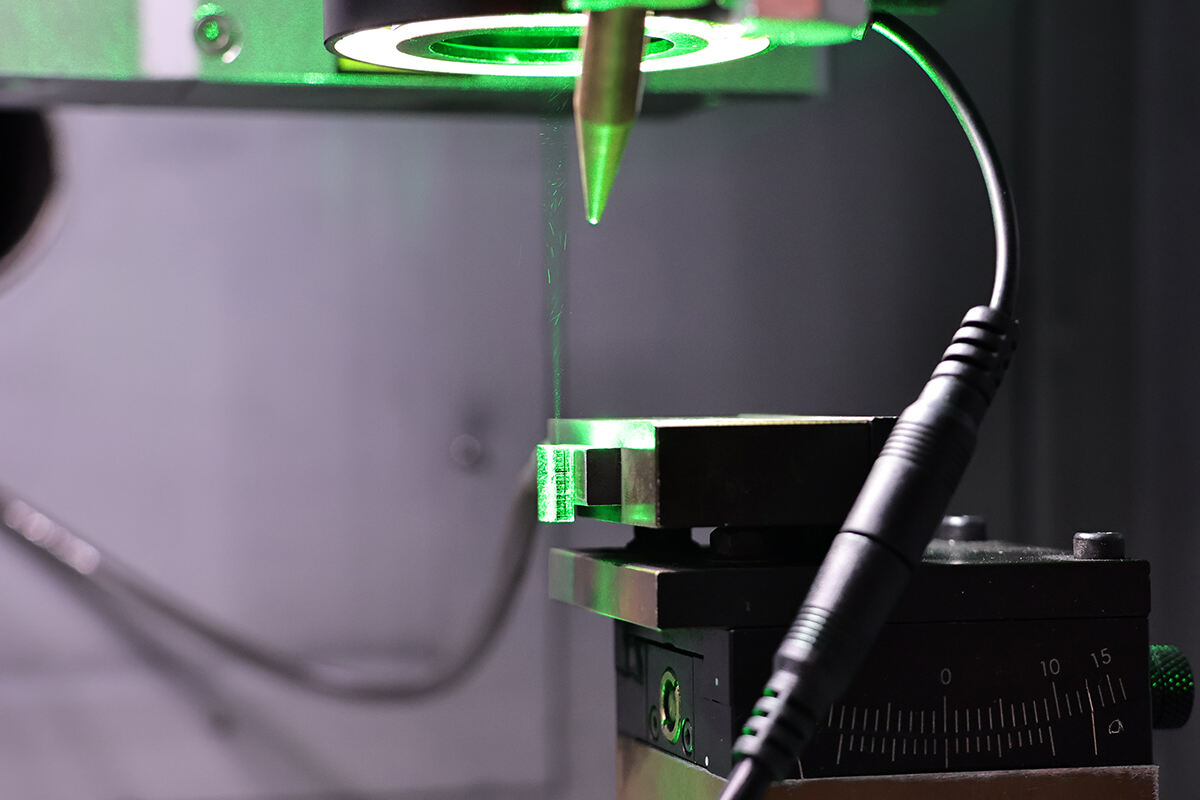

Crysdiam has developed a specialized laser cutting system for diamond seed preparation, achieving mass production of laser slicing, solving problems such as edge collapse and stress cracks, and reducing thermal damage in laser cutting.

Crysdiam’s Laser Slicing System

In addition, the polishing system independently developed by Crysdiam can effectively remove the defect layer of single crystal diamond after slicing, achieve high parallelism precision polishing of 80 microns thick single crystal diamond plate, and complete the preparation of high-quality seed crystals, laying the foundation for the growth of CVD single crystal diamond. 80 microns is thinner than paper, and for materials as hard and brittle as diamond, highly precise control is required.

Crysdiam’s Polishing and Grinding System

Stable growth of large size and thickness single crystal diamond

The CVD reactor independently developed and designed by Crysdiam has achieved breakthroughs in product quality and production efficiency through continuous iteration and optimization.

In terms of product size, Crysdiam can currently produce high-quality single crystal diamond measuring 60mm x 60mm using homoepitaxial growth technology. In terms of product purity, it can reach up to 20 ppb. In terms of controllable doping, boron and nitrogen, the two main doping elements, can be controlled within the range of dozens of ppb, which basically meets the needs of scientific research and industrialization. Hundreds of scientific research institutions and enterprises are clients of Crysdiam, where diamond material has been widely applied in the bottleneck fields such as third-generation semiconductors, quantum crystals, optical windows, and precision sensors.

Homoepitaxial single crystal diamond produced by Crysdiam Technology

In the field of jewelry applications, Crysdiam is one of the few CVD manufacturers in the world that can produce D-E-F color grade lab-grown diamonds as grown, and provide high quality fancy color lab-grown diamonds such as pink and blue, providing clients with customized, standardized, and stable supply.

Crysdiam’s Fancy Color Lab-grown Diamond Products

The rapid development of Crysdiam benefits from a clear strategic positioning. Looking forward, Crysdiam will adopt a diversified product strategy of "high-quality consumer goods plus high-end industrial applications" and is committed to creating a new growth pole for the lab-grown diamond industry.

Highlights

Highlights2024-07-24

2024-07-24

2024-07-23

2024-10-23

White and fancy color lab-grown diamonds in various sizes and shapes;

Offered as certified/uncertified stones, matched pairs, and calibrated parcels.